Repair Solutions for Common Fiberglass Damage

Maintenance of insulated booms on aerial devices and digger derricks is critical to preserving the integrity of the insulating qualities of the machines. While insulated equipment is required to be dielectrically tested each year, daily and periodic inspections of fiberglass components should be performed as directed by the manufacturer.

There are two common types of damage and wear that may affect the integrity of a fiberglass boom. The first, structural damage, is classified according to the type of damage – cuts, bruises or overloads. The second type is wear that occurs where there is contact with other components, such as at boom rests or at fiberglass-to-steel joints.

In both cases, the damage must be assessed to see if it is repairable. Each manufacturer provides information specific to the type and shape of its boom designs. For example, Terex Utilities provides two charts for the equipment it manufactures, which break the damage into minor damage and major damage. The severity of the damage will determine the course of action. Major damage must be reported to the manufacturer for analysis to determine if it can be repaired. Examples include overload damage, complete penetration of the wall or major damage within 24 inches of previously repaired major damage.

Before measuring the depth of a cut or gouge, or the diameter of a bruise, be sure to identify the location of the damage. Location is important because some areas of the boom must support greater amounts of weight than others, which affects whether the damage is considered minor or major.

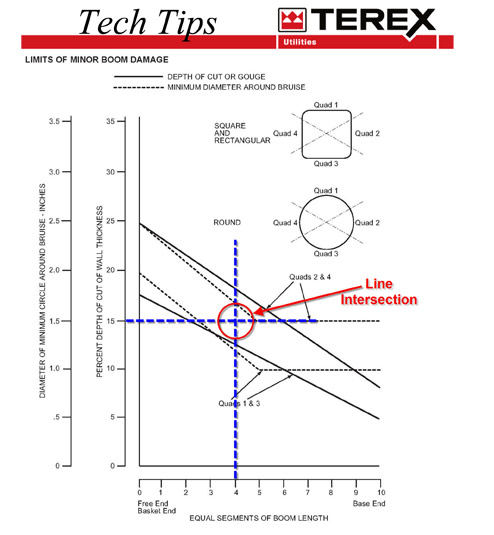

Location is identified at a point along the length of the upper boom and by cross-section. Terex booms are divided into 10 equal lengths from the boom tip (Section 1) to the base (Section 10), and the cross-section is divided into four quadrants. There is one quadrant map for square and rectangular booms, and another quadrant map for round booms. Lower-boom insulating sections are considered as Section 10 because of the short length and loading situation.

An Example of Structural Damage

If the intersecting point is below the solid line for Quadrant 1, the boom is repairable. In this example, the intersecting point falls above the solid line for Quadrant 1, indicating the Major Damage Chart must be used.

A fiberglass boom with a cut on the top would be in Quadrant 1. When measuring the damage, it is determined that the cut is 15% of the thickness of the boom. Note that this measurement does not include the thickness of the finish, which does not add to the structural strength of the boom. Then, divide the boom length into 10 equal parts. In this example, the damage is in Section 4.

Draw intersecting lines from 15% and Section 4 on the Minor Boom Damage Chart. If the intersecting line is below the solid line for Quadrant 1, the boom is repairable. In this example, the intersecting point is above the solid line for Quadrant 1, indicating the Major Damage Chart must be used.

Bruises are evaluated by removing the finish and measuring the diameter of a circle that completely covers the bruise area. Use the scale for bruises to draw the intersecting lines to determine the extent of the damage in a similar way to the previous example.

Common Wear Points

Two common fiberglass wear points are at the boom rest and at fiberglass-to-steel joints. Maintain boom rests by replacing rubber or plastic components as needed. Regularly clean boom rests to remove embedded dirt or gravel.

Improperly maintained joints can lead to corrosion of the steel boom section or allow water or other contaminants to wick into the fiberglass. Rust or dirt that gets inside of a boom can cause dielectric failure. In addition, when moisture penetrates fiberglass windings, the dielectric strength of the fiberglass can be reduced.

To properly seal fiberglass-to-steel joints, first remove the sealant past the point where it has been compromised to allow for thorough inspection. Clean the steel to remove any rust. Naval Jelly and Evapo-Rust are two commercially available products that are suggested for this task. Do not use a rust converter product. Sandblasting may be necessary if minor pitting exists; however, if pitting is extensive, contact the manufacturer to determine if it is safe to repair the boom or if the boom must be replaced.

After priming and painting the area, apply caulking at the joint, ensuring that it adheres to both surfaces. Once you’ve addressed the issues causing wear or damage to the fiberglass, then take proper steps to repair the fiberglass.

Gel Coat Repairs

Damage to the boom’s outer gel coat can also cause dielectric failure. Before making gel coat repairs, refer to the Minor Boom Damage and Major Damage charts to determine if the boom is repairable. Damage to the gel coat should be less than 1 inch in diameter.

Acceptable materials for repairing fiberglass boom surfaces include polyester fiberglass resin; E-Glass fiberglass mat and cloth; white neopentyl glycol gel coat with wax; silicone spray; and hot stick wax. Verify the gel coat to be used does not contain conductive components.

Clean the boom surface by washing it with a product that is not abrasive and does not leave a residue. Rinse, dry and sand the damaged area, then resurface it with the same product. Allow the area to dry. Once dry, spray a thin layer of silicone material or hot stick wax and wipe with a lint-free cloth to remove excess.

Boom Refinishing

If the damaged area is larger than 1 inch in diameter or the boom needs to be refinished, start by cleaning the surface with something that is not abrasive and does not leave a residue. Remove the caulk seals of the fiberglass-to-steel joints if there is any visible rust.

Allow the boom to dry for 24 hours in an environment with less than 25% relative humidity. The recommended temperature is between 100 to 140 degrees Fahrenheit.

Thoroughly sand the outside surface less than 0.015 inches (0.38 millimeters). Once sanded, only handle the boom using clean gloves. Oil and salt from bare hands can contaminate the surface. Additionally, do not expose the sanded boom to humidity over 40%. At this point in the process, it is important to move as quickly as possible from unfinished to refinished. If the reason for refinishing the boom is because it failed a dielectric test, you may want to retest after removing the gel coat to determine if that solved the problem. Part of the initial inspection should have included a visual inspection of the interior for oil leaks, conductive hoses or indications of flashover.

Resurface the boom, referring to manufacturer instructions for minimum and maximum thickness range as well as how thick of a coat is permitted in one application. Air-dry the boom at 77 degrees Fahrenheit for 12 to 24 hours, then caulk fiberglass-to-steel joints. A gel coat with a wax layer or the addition of hot stick wax or a silicone layer is recommended to encourage water to bead on the surface.

The final step after reassembly is to complete an operational test from lower and upper controls. Successful completion of a periodic dielectric test per ANSI A92.2 is also required. Before placing the unit back in service, repair any other issues that caused the damage to prevent future damage.

Remember that regular inspections are critical to maintaining the integrity of your insulated machine. Understanding the types of damage and proper repairs will help mitigate the issues found. Regardless, throughout the process, the manufacturer should be consulted for best results.

About the Author: Jason Julius oversees technical support and training at Terex Utilities. Information for this article came from the company’s Tech Tips #23, #129 and #149. These and other technical support documents are available via the Technical Support tab at www.terex.com/utilities.